54 Edmund Road Brandon

Suffolk IP27 0XA

Phone Number

0800 246 1273

Send Your Mail

sales@deionisedwater.org

Suffolk IP27 0XA

0800 246 1273

sales@deionisedwater.org

DeionisedWater

December 21, 2025

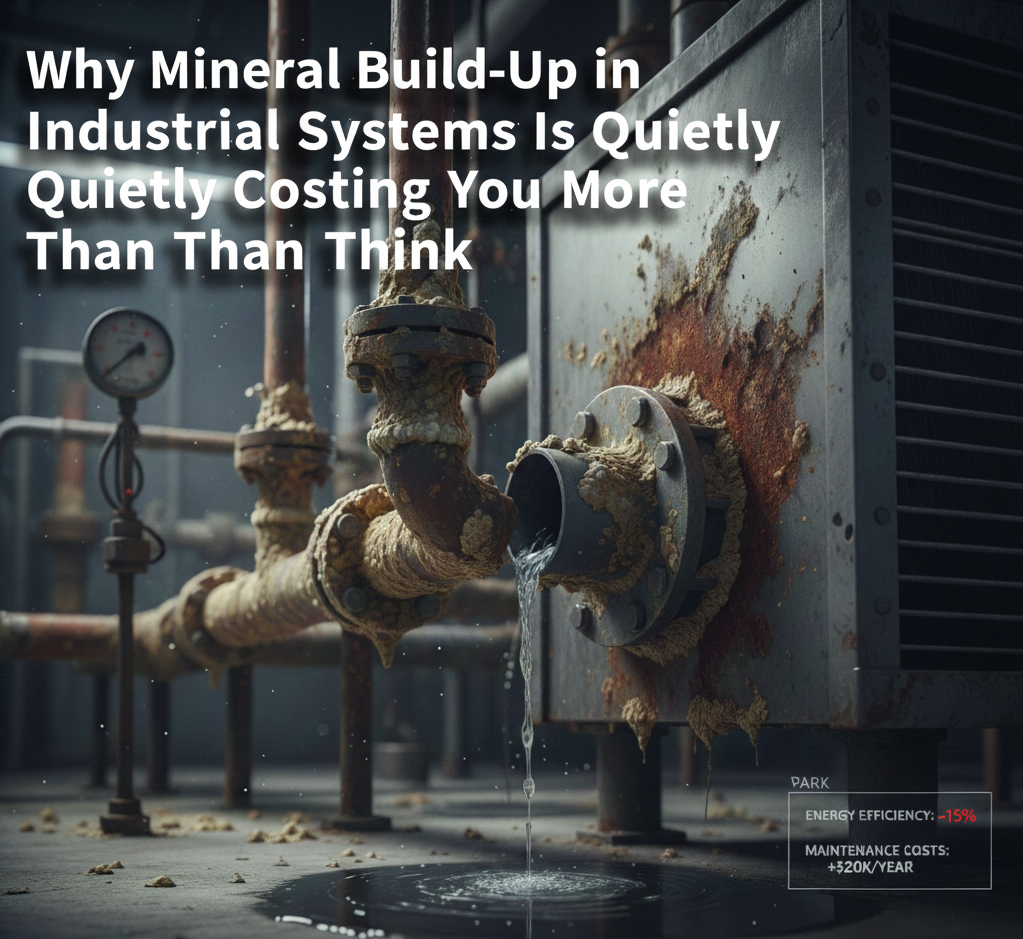

If you’ve ever managed a factory, plant, or any industrial setup with boilers, cooling towers, or heat exchangers, you’ve probably dealt with scaling issues at some point. It’s one of those problems that doesn’t scream for attention – no alarms, no sudden breakdowns. Instead, it sneaks up: energy bills creep higher, equipment needs more maintenance, and things just don’t run as smoothly as they used to.

The truth is, mineral build-up in industrial systems is one of the most common – and most overlooked – reasons for reduced efficiency and rising costs. From steam boilers to cooling loops and manufacturing rinse lines, those tiny dissolved minerals in your water supply can cause big headaches over time. And the frustrating part? Most of it is completely preventable.

In this post, we’ll break down where these minerals come from, what they actually do inside your systems, and why getting your water quality right (especially with deionised water) can save you a lot of money and hassle in the long run. For a simple explanation of what makes water “hard” in the first place, check out this overview from the USGS Water Science School.

Most industrial facilities pull water from the mains supply, boreholes, or recycled sources. Even if it looks crystal clear, that water almost always contains dissolved minerals like:

This is what we call hard water. These minerals aren’t visible – they’re completely dissolved – which is why they slip past basic filters and end up circulating through your pipes, boilers, and heat exchangers.

Once they’re in a closed or semi-closed system, there’s no easy way out. As water heats, cools, or evaporates, those minerals start dropping out of solution and sticking to surfaces. It’s a slow process, but it never stops unless you interrupt it.

The damage isn’t dramatic at first, but it compounds quickly.

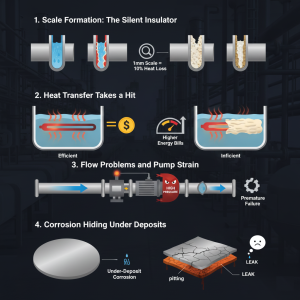

Scale Formation: The Silent Insulator When water temperature changes (especially in heating processes), minerals precipitate and form a hard layer called scale on pipes, heat transfer surfaces, valves, and fittings.

This scale might look harmless – just a thin white or brownish coating – but it acts like insulation. Even a millimetre or two can seriously reduce how well heat moves through your system.

Heat Transfer Takes a Hit In boilers and heat exchangers, scale forces the system to work harder. You need more fuel or electricity to reach the same temperatures because heat can’t transfer efficiently from the heating element to the water.

Studies show that just 1mm of scale can cut heat transfer efficiency by over 10%. In a large facility, that translates directly to thousands of dollars in extra energy costs every year.

Flow Problems and Pump Strain As scale narrows pipe diameters, water flow slows down. Pumps have to push harder against increased resistance, leading to higher pressure, more wear on seals and motors, and eventually premature failure.

It’s like trying to drink through a straw that’s slowly clogging – everything takes more effort.

Corrosion Hiding Under Deposits One of the sneakiest problems is under-deposit corrosion. Scale traps moisture against metal surfaces, creating perfect conditions for pitting and rust to develop out of sight.

Oxygen levels vary under the deposits, setting up tiny electrochemical cells that eat away at the metal. By the time you notice a leak, the damage is often extensive. For a deeper dive into how this works, this guide on under-deposit corrosion from Corrosionpedia explains it clearly.

Mineral build-up doesn’t just hurt equipment – it hits your bottom line in ways that aren’t always obvious.

Many facilities accept scaling as “just part of running the plant.” But it doesn’t have to be.

Some systems are particularly vulnerable because they rely heavily on efficient heat transfer and flow:

If your operation depends on any of these, mineral build-up is likely costing you more than you realise.

Here’s a common misconception: many facilities install good sediment filters and think they’re protected.

Filters are great for catching dirt, rust particles, and debris. But they do nothing for dissolved minerals – the ones that cause scale.

Calcium, magnesium, and silica simply pass straight through. That’s why even well-filtered systems can still suffer from severe scaling over time.

This is where deionised water changes everything.

Through ion-exchange processes, deionised water has virtually all dissolved minerals and salts removed. No calcium. No magnesium. No ions left to form scale.

The result?

Because there’s nothing left to precipitate, mineral build-up simply can’t happen.

Deionised water is widely used in industries where purity matters – from manufacturing and metal finishing to pharmaceuticals and food processing. You can see common applications here: applications of deionised water.

For industrial facilities, using industrial-grade deionised water in makeup water, rinse processes, or closed loops is one of the most effective ways to protect equipment and control costs.

Once scale has formed, removing it usually means:

All of which cost time and money.

Using purified water from the start prevents these problems entirely. It’s a small upfront investment that pays for itself many times over through lower energy use, reduced maintenance, and longer equipment life.

Mineral build-up in industrial systems is one of those slow, silent problems that can go unnoticed for years – while quietly draining efficiency and driving up costs.

But it doesn’t have to be inevitable.

Understanding where these minerals come from and how they cause damage is the first step. The next is taking control of your water quality.

For systems that depend on reliable performance, using deionised water isn’t just good practice – it’s smart business.

Your equipment will run more efficiently, last longer, and cost less to operate. And in the end, that’s what really matters.

(Word count: approximately 1510)

What causes mineral build-up in industrial systems? It’s mainly dissolved calcium, magnesium, and other minerals in hard water that precipitate out as scale when temperature or pressure changes.

Can scale damage equipment permanently? Yes – it reduces efficiency, causes overheating, restricts flow, and leads to hidden corrosion that can cause leaks and failures.

Will better filtration stop scaling? No. Filters remove particles, but dissolved minerals pass through. You need purified water to prevent scale.

Why does deionised water work so well? It contains no dissolved ions, so there’s nothing left to form scale deposits.

Which systems benefit most from deionised water? Boilers, cooling systems, heat exchangers, rinse processes, and any closed-loop systems where efficiency and reliability matter.

Have you noticed scaling issues in your facility? Feel free to share your experience in the comments – we’d love to hear how you’re managing it!

Suffolk IP27 0XA

sales@deionisedwater.org